Thermoplastic profiles and tubes, for more than 30 years.

PTH, a leading business in the development and production of Plastic Profiles and Tubes, is the concrete result of a close partnership between one of the most important business operating in the sector of construction of moulds dedicated to extrusion, and technicians who specialise in the extrusion of plastic materials.

Technical consultation and design of products.

Our experience acquired and perfected over the years, combined with abilities at design and at the use of the best software out there, gives us the fullest and most detailed attention to the development and production of the profiles and tubes we extrude.

Latest News

Light + Building Frankfurt 2024

Come find us at the Light+Building fair in Frankfurt. The world’s number one trade fair as an international meeting place for …

NEW SMART CLIP RANGE

The PTH team is pleased to introduce the new SMART CLIP product range, which is designed and developed to make …

The importance of designing stamps for the extrusion of profiles in PC and PMMA

The importance of designing stamps for the extrusion of profiles in PC and PMMA La progettazione di stampi per l’estrusione …

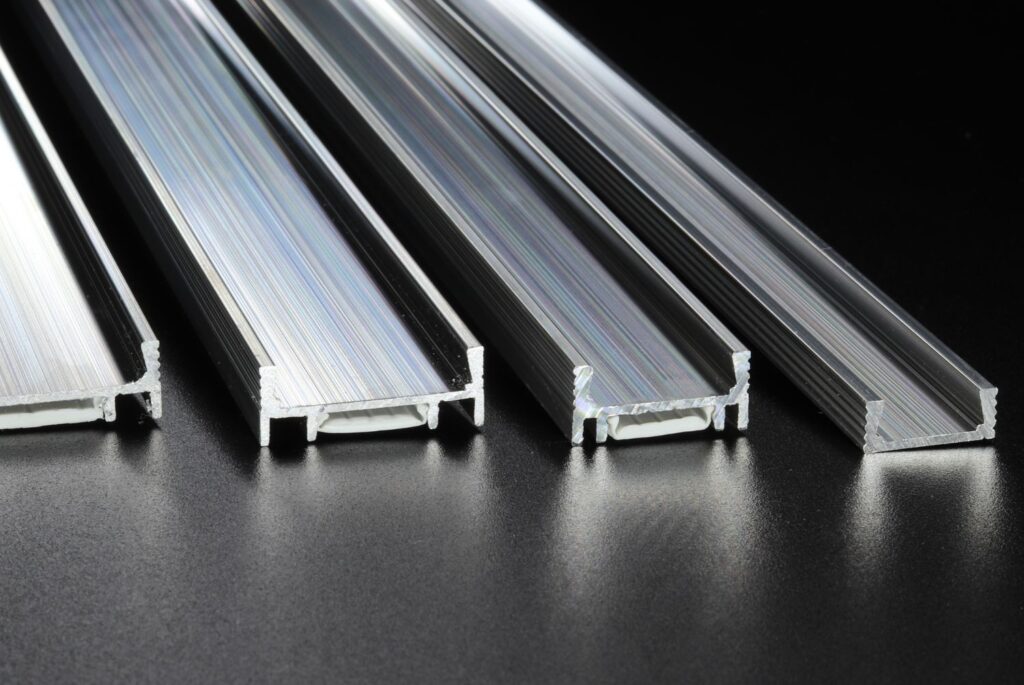

What are LED alluminium profiles?

The technology of LED strips enables the creation of versatile lighting solutions that are safe, easy to install, of low …

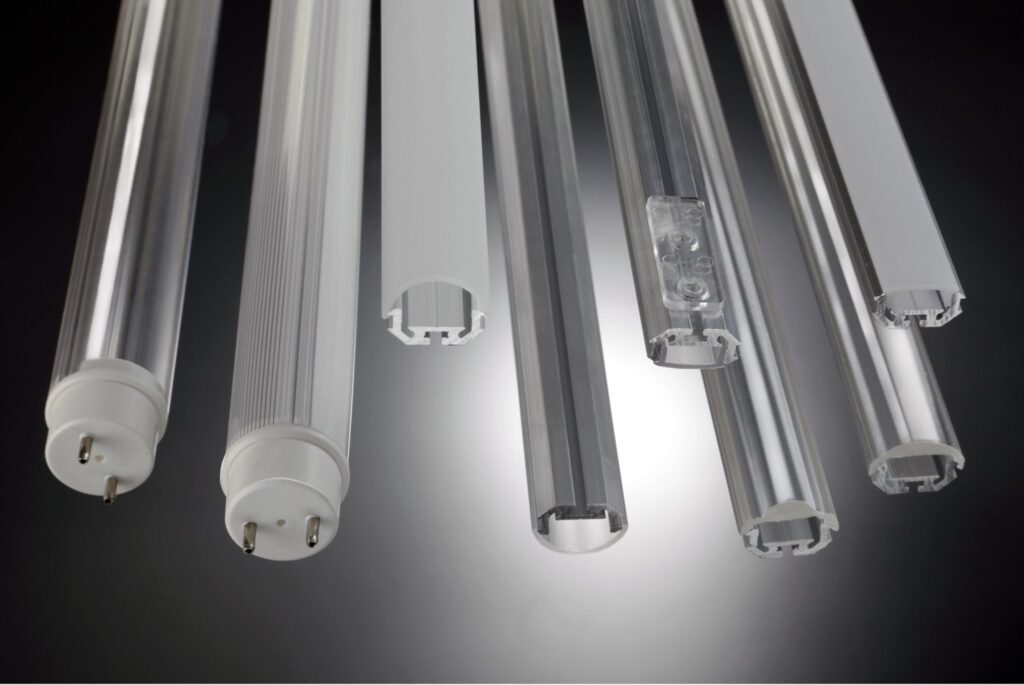

What are polycarbonate and methacrylate tubes, and when are they used?

Polycarbonate and methacrylate tubes are useful for the production of numerous functional and design objects. Polycarbonate and PMMA are thermoplastic …

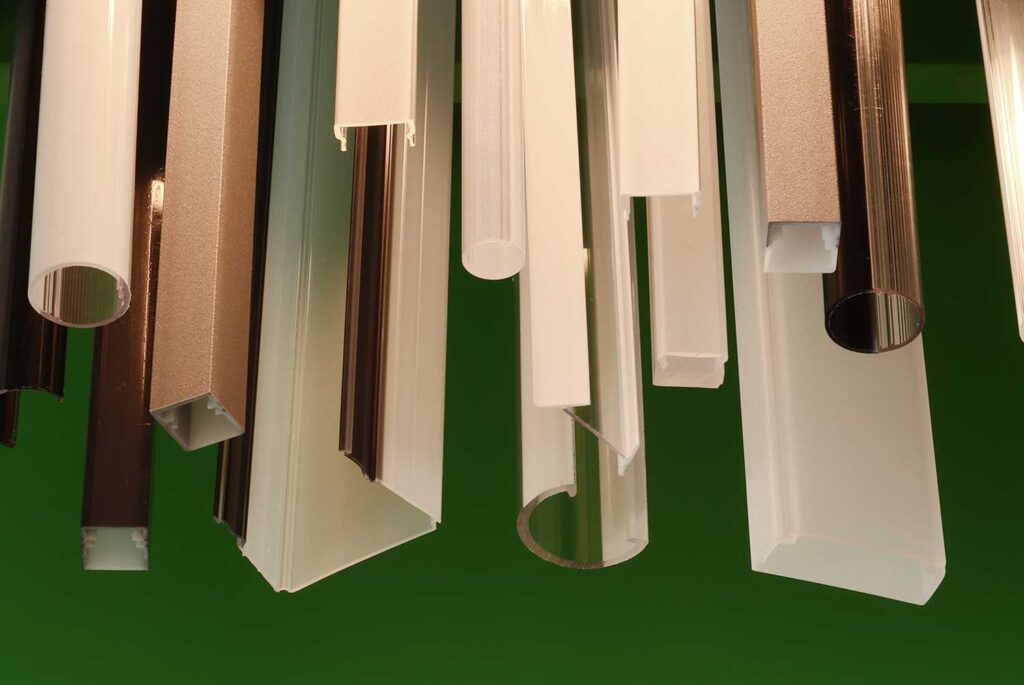

Extrusion of polycarbonate and methacrylate profiles: what does it involve?

The extrusion of polycarbonate and methacrylate profiles and other polymers is a process that transforms plastic materials into real objects …

The design of glazing bead profiles and partition walls

Glazing bead profiles: Companies that specialise in the creation of manufactured plastic products focus on processes of plastic extrusion for …

New MIMIC ALU range

PTH, always attentive to the needs of the national and international market, will, at the Fiera Light+Building in Frankfurt, present …

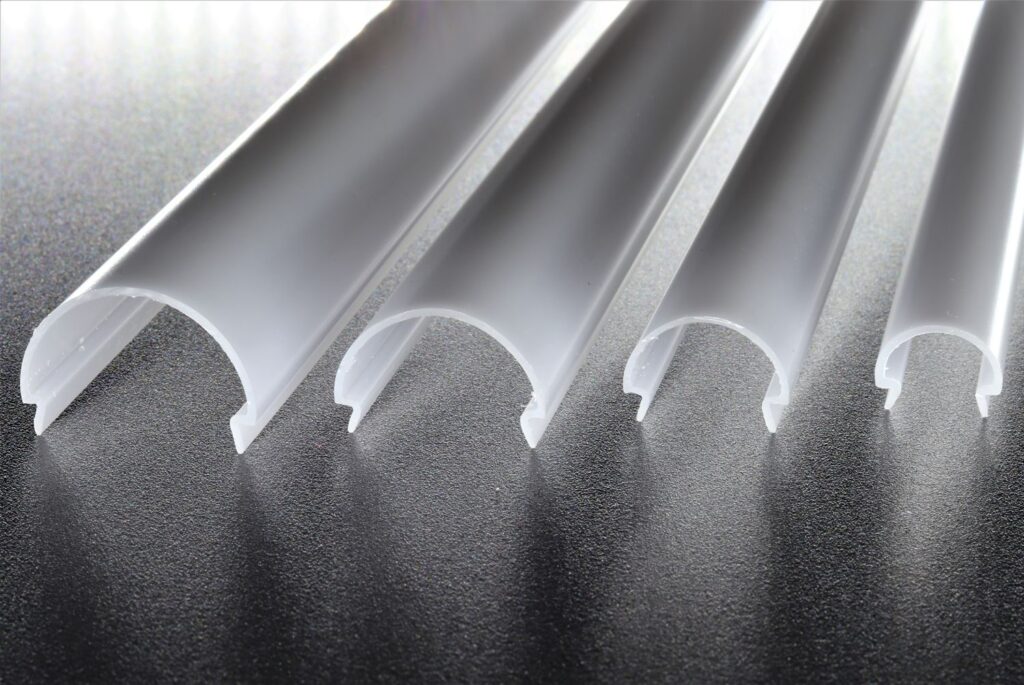

A solution for custom-made illumination

PTH has found a solution as simple as it is ingenious. Henceforth you can find on our site all the …

Light + Building Frankfurt 2022

Come find us at the Light+Building fair in Frankfurt. The number one fair in the world for the presentation of the …