The extrusion of polycarbonate and methacrylate profiles and other polymers is a process that transforms plastic materials into real objects and profiles. Starting with polymers in powder or in granules, it is possible to homogenise the materials and give them the shape that you desire. Without extrusion of the manufactured products, it would not be possible to create the common shopping bag, packaging materials, string, and, in general, plastic profiles in common use.

What do we mean by extrusion?

Extrusion is a type of processing of plastic used in the manufacturing industry. This process enables the moulding of thermoplastic materials such as polycarbonate and methacrylate, thus obtaining various kinds of products, such as tubes and profiles for a range of applications.

Plastic extrusion occurs through specific machines capable of transforming materials using personalised templates, called matrices.

Polycarbonate and methacrylate: their primary features

Policarbonato e metacrilato sono materiali termoplastici trasparenti, entrambi utilizzabili al posto del vetro, ma che presentano caratteristiche differenti.

Il policarbonato è un polimero che deriva dal bisfenolo A e risulta più leggero e molto più resistente del vetro. Si tratta di un mate

Polycarbonte and methacrylate are transparent thermoplastic materials, and both can be used instead of glass. However, they present different features.

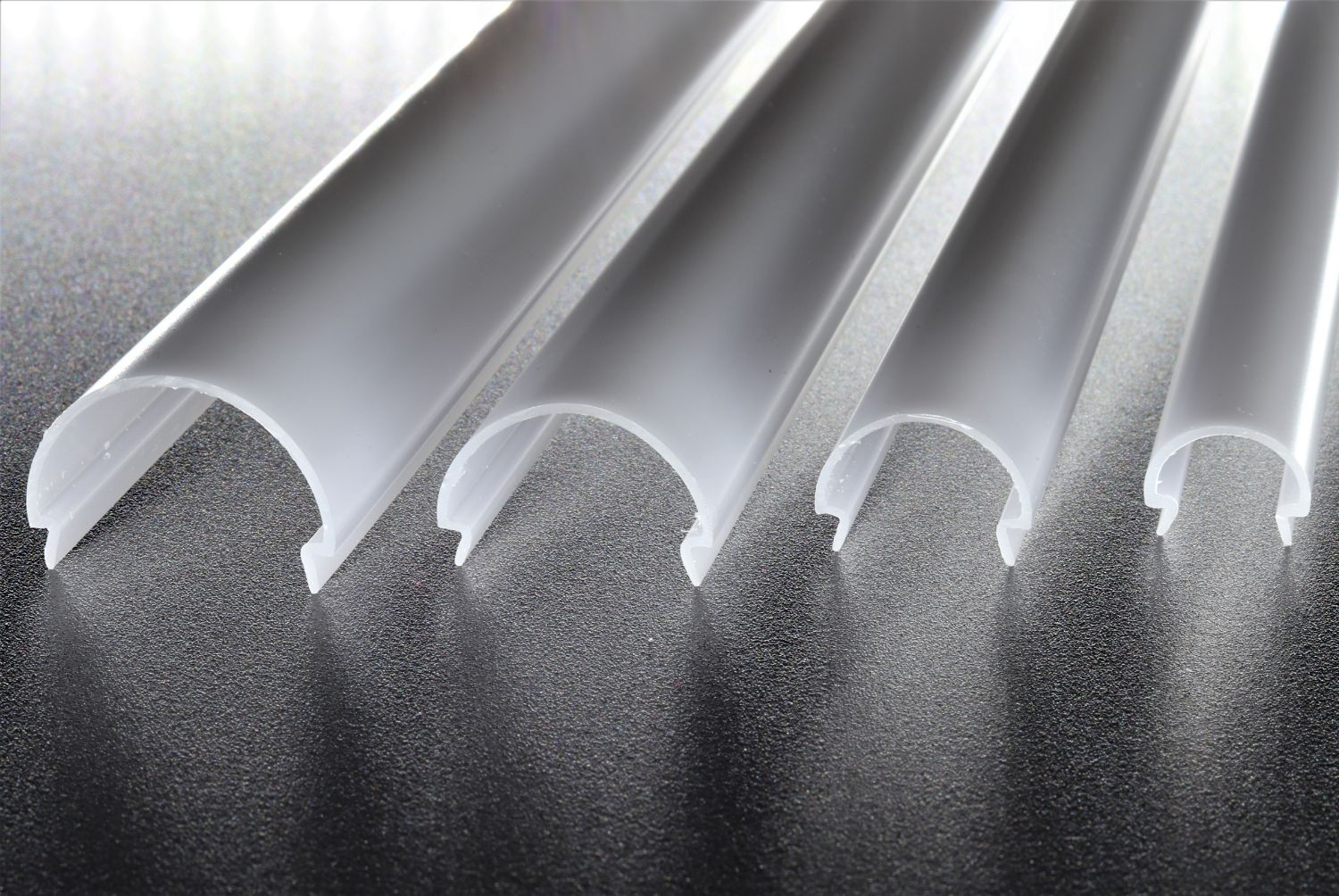

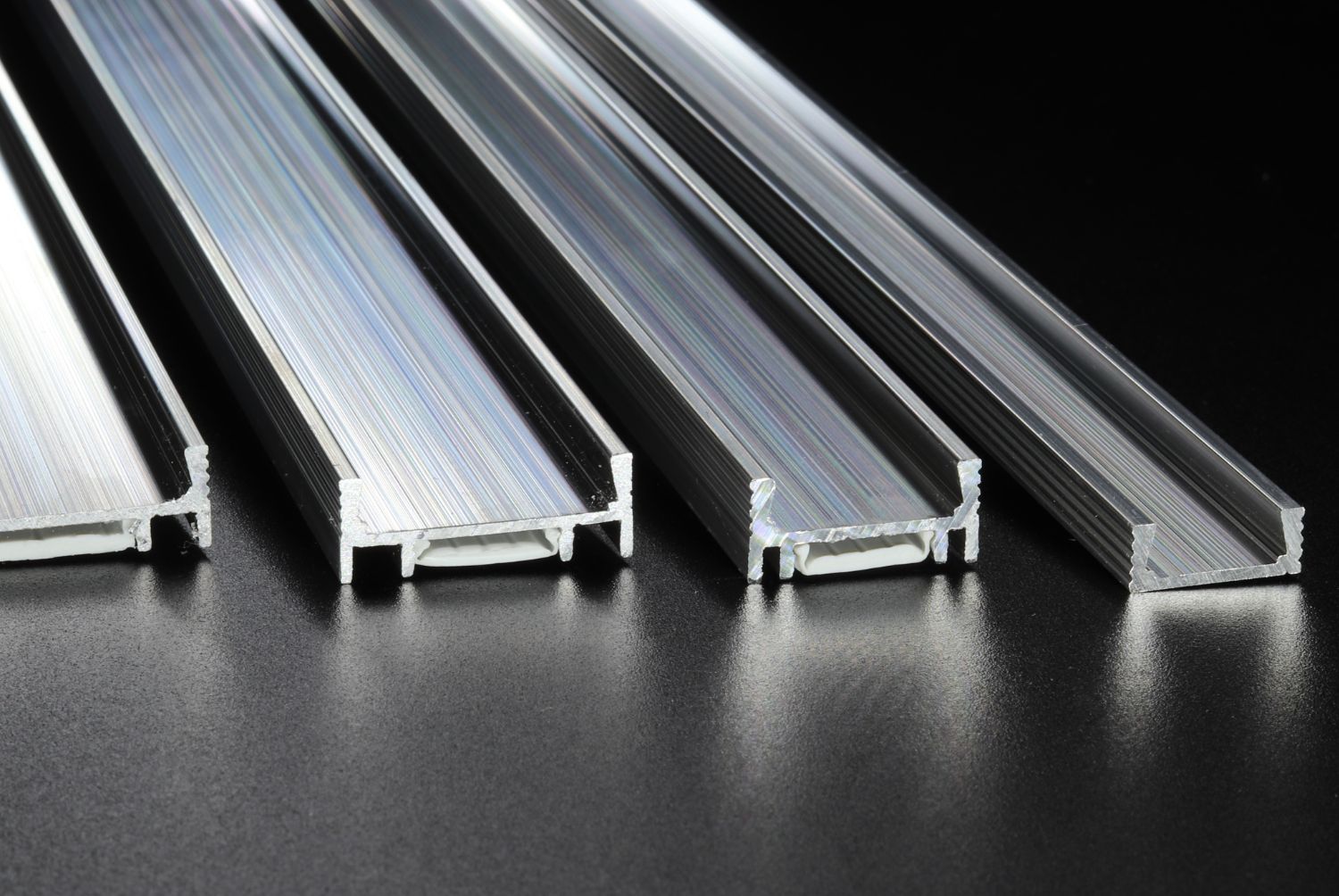

Polycarbonte is a polymer that derives from bisphenol A and is lighter and more resistant than glass. It is a plastic material that is extremely easy to work, elastic, and particularly resistant to impact. Once extruded, polycarbonte can be used to construct various objects, such as:

- lamps;

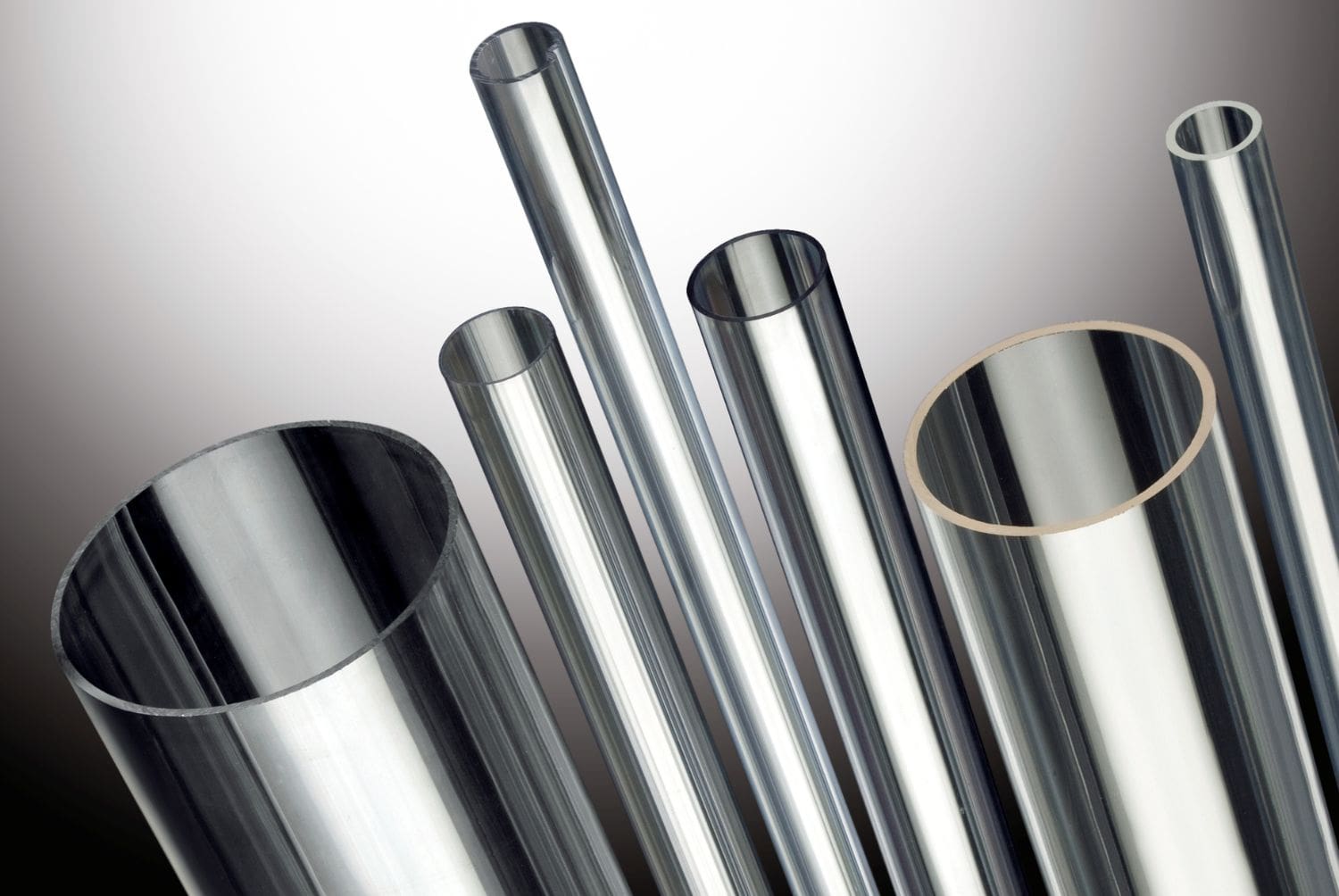

- tubes;

- diffusers;

- covers;

- conduits;

- linear lenses.

Polycarbonte is less transparent than glass and methacrylate and, when exposed to UV rays, yellows noticeably. Nevertheless, the significant advantage of objects in polycarbonte lies in their considerable mechanical resistance, especially when compared to glass.

Methacrylate or PMMA, often called Plexiglass, is no less than a compound of methyl methacrylate polymers of a great number of objects. Once it is extruded, methacrylate can assume various forms, such as:

- sheets;

- tubes;

- diffusers;

- linear lenses;

- covers;

This thermoplastic material, which is 100% recyclable, is more transparent than glass and extremely lucid and smooth. Comparing it, as before, to glass, methacrylate is lighter and possesses a greater impact resistance (of 17 volts). PMMA, nevertheless, is not an infrangible material- indeed, it is necessary to keep it away from open flames because it can burn in the presence of temperatures that surpass 460 degrees. The advantages of objects constructed in methacrylate include:

- transparency

- a wide range of colours

- excellent resistance to acids and cleaning products.

The choice between polycarbonate and methacrylate, therefore, depends upon everyone’s specific needs.

Why should you rely on plastic extrusion?

Plastic extrusion is necessary to transform polymers into objects that can be used. Through extrusion, it is possible to give shape to every kind of progect that invovles the use of thermoplastic materials. The majority of companies can create profiles and tubular elements that are totally personalised, satisfying all the specific needs of clients.

Are you looking for a company that focuses on the extrusion of polycarbonate and methacrylate profiles and tubes? Get in touch

Do you need profiles or polycarbonte or methacrylate tubes? You can count on us at PTH Group– we have specialised in the extrusion of thermoplastic materials for years. Our company can guarantee you the production of personalised stamps, the extrusion of raw materials, and the creation of the profiles and tubes you need. PTH uses the latest technology for the extrusion of thermoplastic materials, as well as much experience in the creation of profiles for every industrial and commerical use. Contact us via telephone or vist our site. You will not regret it.