The importance of designing stamps for the extrusion of profiles in PC and PMMA

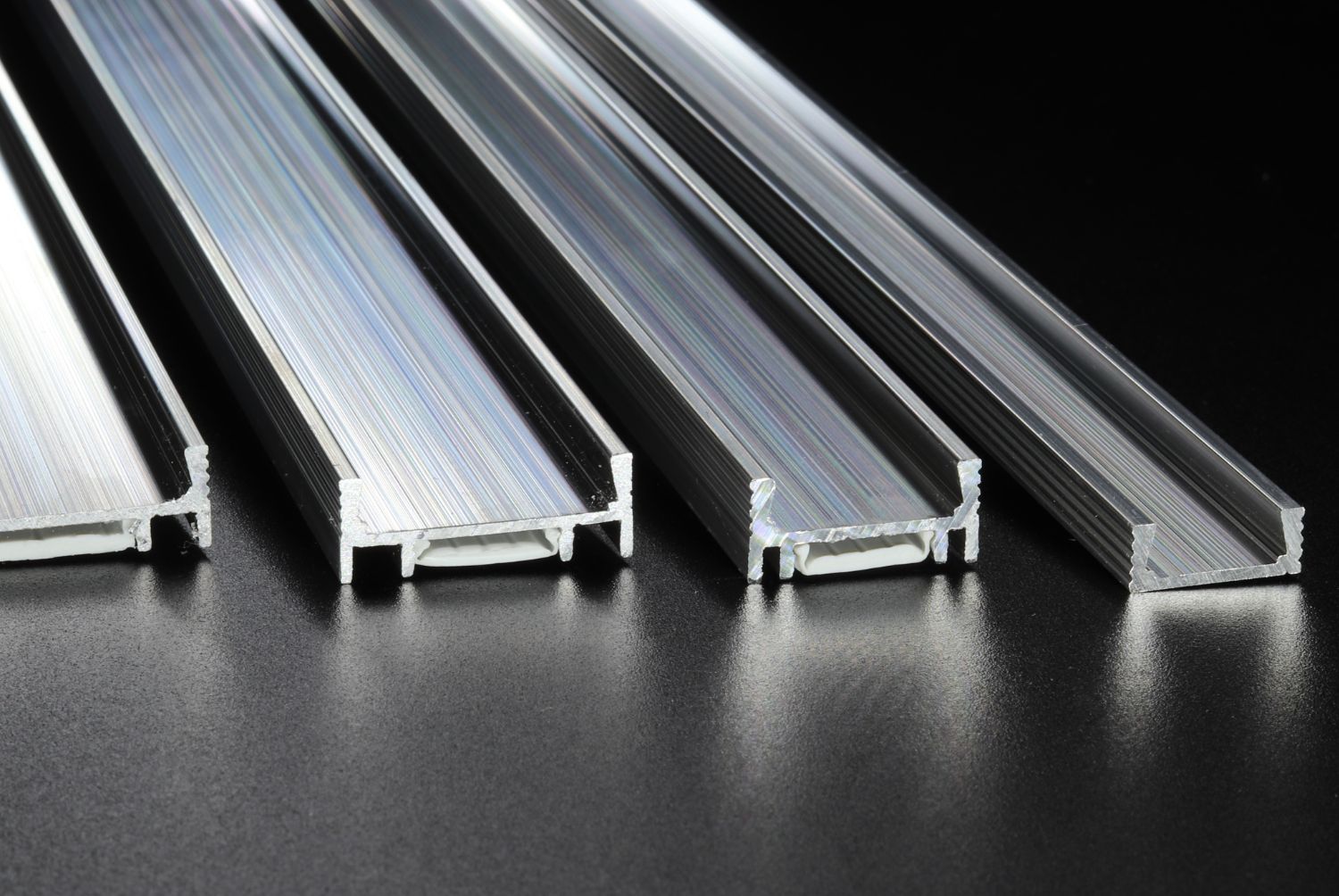

La progettazione di stampi per l’estrusione di profili in policarbonato (PC) e metacrilato (PMMA) permette di creare prodotti finali personalizzati.

L’estrusione della plastica è un tipo di lavorazione possibile grazie a specifici macchinari che utilizzano stampi per materiali termoplastici. La creazione di questi stampi, attraverso tecnologie di progettazione, risulta fondamentale al fine di ottenere la forma definitiva del prodotto che si desidera.

The advantages of the plastic extrusion process

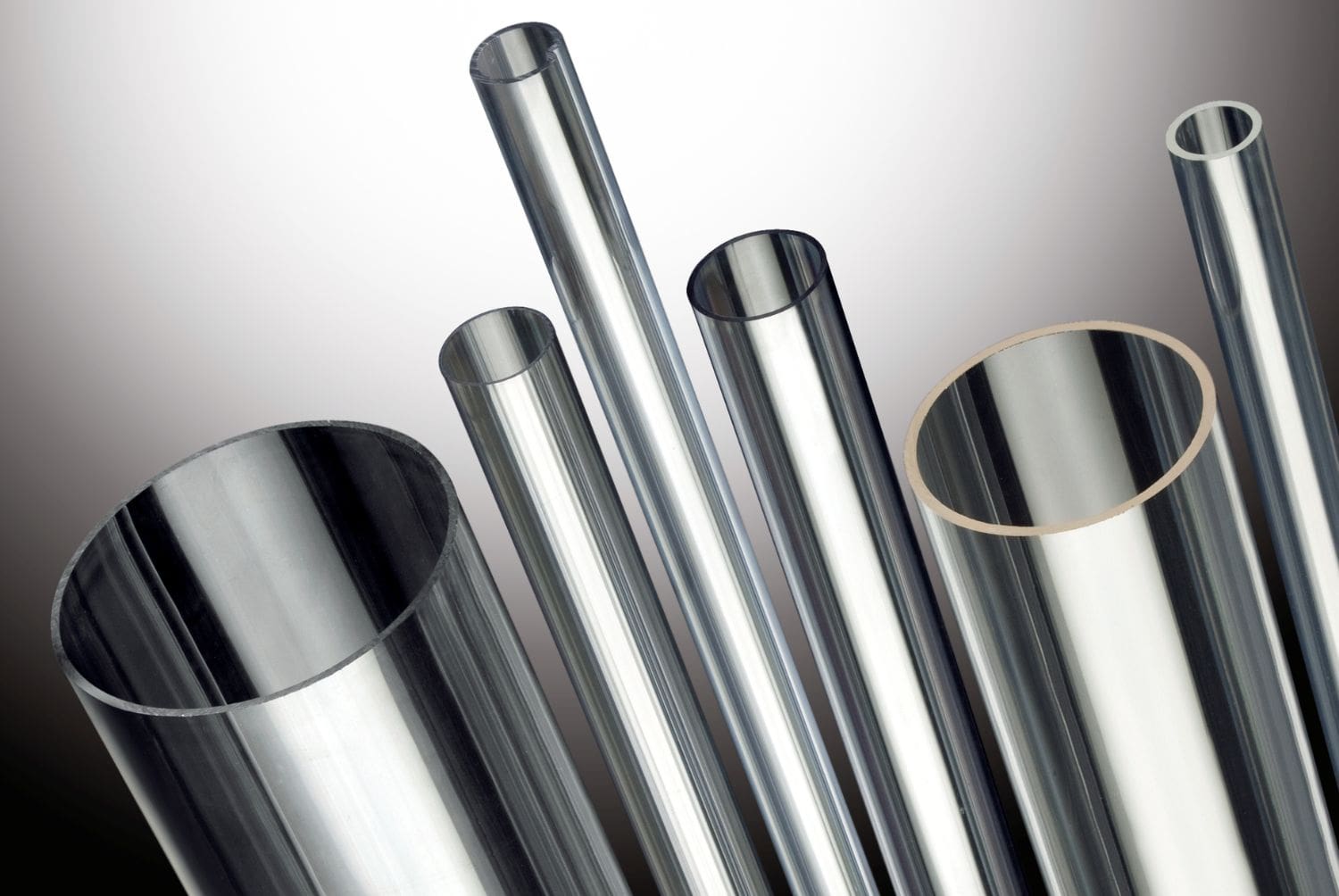

The process of plastic extrusion, and in particular the extrusion of PMMA and PC, helps obtain plastic tubes and profiles that can be used in various sectors. Thanks to this technique of moulding plastic, methacrylate and polycarbonate (whether in a granular state or in powder) can assume the shape of specific tubes and profiles that can be used in the construction of components for illumination, for cars, for medical devices, and much else.

Extrusion occurs by inserting the coarse plastic material into a machine that will heat and melt it, to then push it at a constant pressure through a stamp (or matrix) that will give it a shape. Finally, the finished product is cooled.

The most significant advantage derived from the extrusion process is the personalisation of the shapes of the finished products. Through the use of stamps for thermoplastic materials, designed with programs such as CAD and CAM, extrusion can mould the materials for a specific project.

What kind of materials are PC and PMMA?

PC, or polycarbonte, and PMMA, or methacrylate, are thermoplastic materials utilised for the production of many kinds of objects. Often used to substite glass components, PC and PMMA are polymers that are extremely versatile and easy to mould through extrusion.

For example, in the lighting sector, PMMA and PC are largely used for the contruction of diffusers, screens, and lenses for LED lamps, given their lightness, transparency, versatility, and strong impact resistance.

How are stamps for the extrusion process designed?

Stamps for thermoplastic materials or matrices used in the extrusion process are components that give a shape to coarse polymers. The matrices are designed through the use of specialised software for design and production, such as CAD and CAM- respectively, Computer-Aided Design and Computer-Aided Manufacturing.

These are professional programs for digital design that enable companies that produce profiles to create stamps for thermoplastic materials that give the extruded product the size and shape desired by their client.

Do you need a company that focuses on the extrusion of profiles in PC and PMMA? Inquire further

Are you looking for a company that focuses on the creation of stamps for the extrusion of profiles? You can count on us at PTH Group, experts in techniques for the processing of PC and PMMA.

Our company has more than thirty years’ worth of success stories, and puts at the disposal of all our clients a team of experts who can find the perfect solution for every need.

Through the use of cutting-edge software, we can offer you a high quality service for the creation of thermoplastic stamps based on a personalised project. Consult the PTH website or contact us via telephone. You will not regret it.