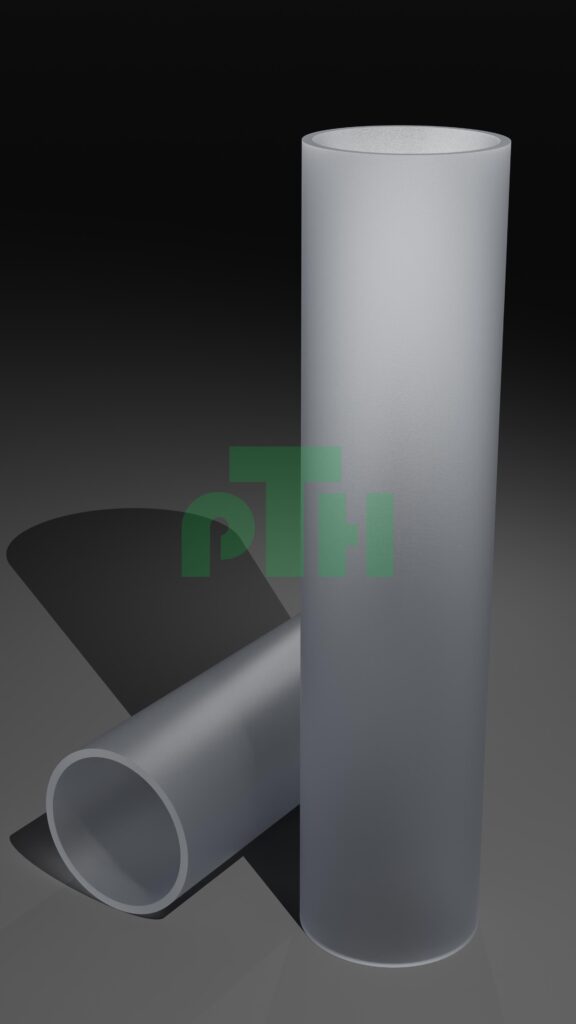

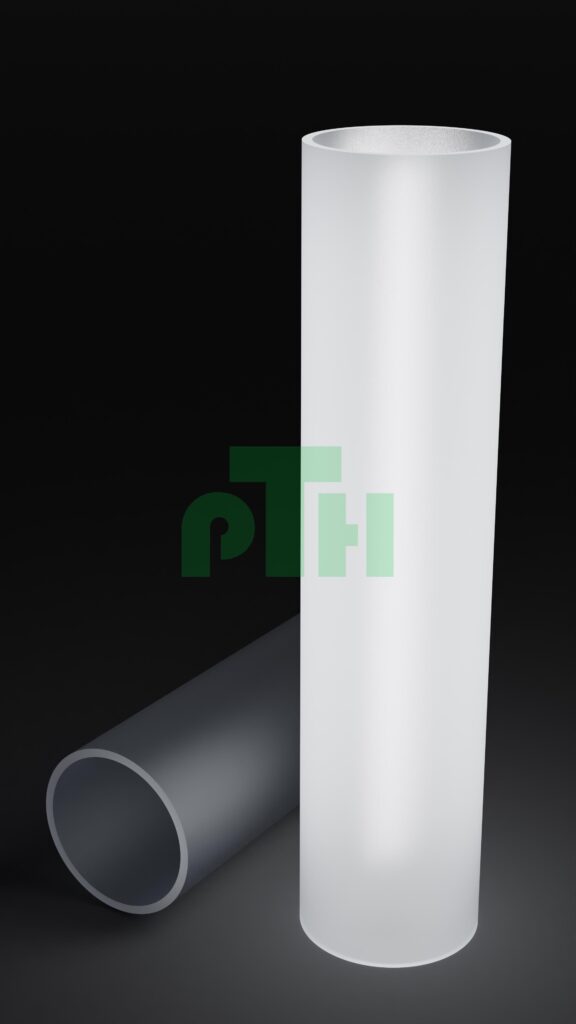

PMMA Tubes

The PMMA tubes produced by PTH GROUP are the ideal solution for those seeking high transparency, brilliance, and impeccable aesthetic quality. Thanks to the use of state-of-the-art extrusion technologies and careful material control, PTH GROUP guarantees tubes with perfectly uniform surfaces, excellent light distribution, and dimensional stability over time.

The technical department is constantly engaged in selecting the most high-performance polymers, ensuring outstanding results even for the most demanding applications, such as those in the lighting, architectural, and industrial design sectors.

PMMA tubes are available in a wide range of outer diameters from 4 mm to 300 mm, with various finishes and transparency levels, to meet every aesthetic and functional requirement.

At PTH GROUP’s in-house showroom, customers can view a broad selection of samples, which can also be shipped on request, allowing them to directly evaluate the quality and visual performance of the material.

The technical department is constantly engaged in selecting the most high-performance polymers, ensuring outstanding results even for the most demanding applications, such as those in the lighting, architectural, and industrial design sectors.

PMMA tubes are available in a wide range of outer diameters from 4 mm to 300 mm, with various finishes and transparency levels, to meet every aesthetic and functional requirement.

At PTH GROUP’s in-house showroom, customers can view a broad selection of samples, which can also be shipped on request, allowing them to directly evaluate the quality and visual performance of the material.

PMMA Tubes

Methacrylate (PMMA) tubes are extruded with transparent, opal, and satin finishes. They feature high light transmission, no yellowing, transparency, and a breaking point superior to glass.

PMMA tubes are available in a wide range of outer diameters, ranging from 4 mm to 300 mm.

Technical Properties of PMMA Tubes

- Excellent light transmission value

- UV stabilization

- Homogeneous light diffusion

- Flame retardant propagation

- Excellent fire resistance

- UL94 V2 and UL94 V0 certification

- High mechanical strength

- High impact resistance

- Chemical resistance

- Tensile and yield strength

- Resistance to high temperatures

PMMA Tube Applications

- Tubes for Lighting

- Tubes for LED

- Tubes for Design and Furniture

- Tubes for Liquid Transport

- Tubes for Level Indicators

Available Diameters – PMMA Tubes

*Also available with internal prismatic structure.

Wall thickness and other diameters available upon request.

**Indicative, but may vary depending on thickness.

| Outer - Ø in mm | Min. production volume (m) |

|---|---|

| 4 | 2000 |

| 4,7 | 2000 |

| 5 | 2000 |

| 6 | 1500 |

| 7 | 1500 |

| 8 | 1500 |

| 9 | 1500 |

| 9,5 | 1500 |

| 10 | 1500 |

| 11 | 1000 |

| 12 | 1000 |

| 13 | 1000 |

| 14 | 1000 |

| 15 | 1000 |

| 15,5 | 1000 |

| 16 | 1000 |

| 17 | 1000 |

| 18 | 1000 |

| 19 | 1000 |

| 20 | 1000 |

| 20,5 | 1000 |

| 21 | 1000 |

| 22 | 1000 |

| 23 | 1000 |

| 24 | 1000 |

| 25 | 1000 |

| 25,4 | 1000 |

| 26 | 1000 |

| 27 | 1000 |

| 28* | 1000 |

| 30* | 1000 |

| 32* | 1000 |

| 32,5* | 1000 |

| 33* | 1000 |

| 34* | 1000 |

| 35* | 1000 |

| 36* | 1000 |

| 38* | 1000 |

| 40* | 500 |

| 42,5* | 500 |

| 44* | 500 |

| 45* | 500 |

| 50* | 500 |

| 52* | 500 |

| 56* | 500 |

| 59* | 500 |

| 60* | 500 |

| 63* | 500 |

| 64* | 500 |

| 65* | 500 |

| 66* | 500 |

| 67* | 500 |

| 68* | 500 |

| 70* | 250 |

| 75* | 250 |

| 78* | 250 |

| 80* | 250 |

| 83* | 250 |

| 84* | 250 |

| 90* | 250 |

| 95* | 250 |

| 96* | 250 |

| 100* | 250 |

| 110* | 250 |

| 120* | 250 |

| 125 | 250 |

| 130 | 250 |

| 133 | 250 |

| 134 | 250 |

| 140 | 250 |

| 145 | 250 |

| 150 | 250 |

| 152 | 250 |

| 160 | 250 |

| 170 | 250 |

| 178 | 250 |

| 180 | 250 |

| 185 | 250 |

| 200 | 250 |

| 230 | 250 |

| 240 | 250 |

| 250 | 250 |

| 300 | 250 |

Customized Processing and Tailored Packaging

PTH can meet customer requests by performing both special processing and custom applications and packaging on demand.

-

Precise cutting

-

Drilling*

-

Prototyping

-

Protective coating application

-

Double-sided adhesive application

-

Special packaging

* Only for PC and subject to approval by the technical department