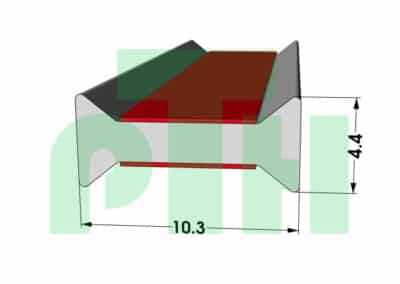

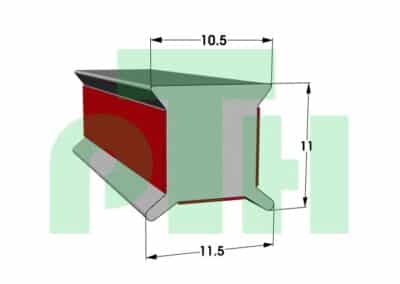

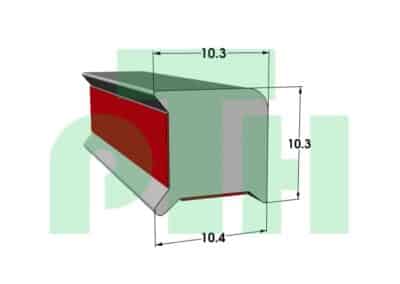

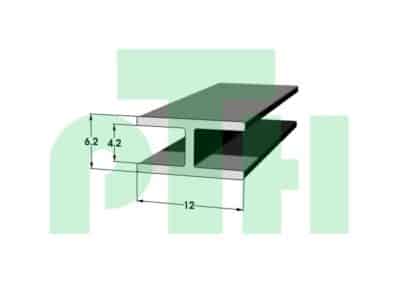

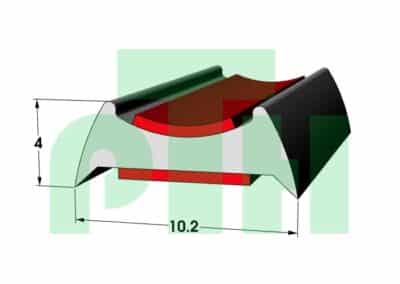

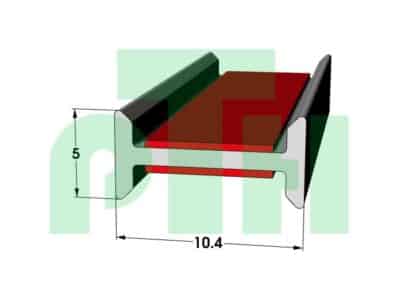

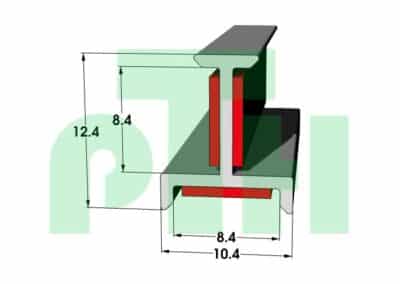

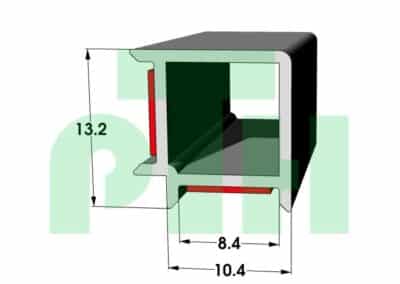

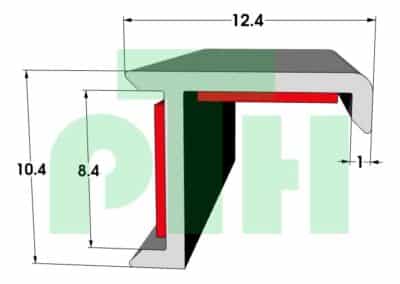

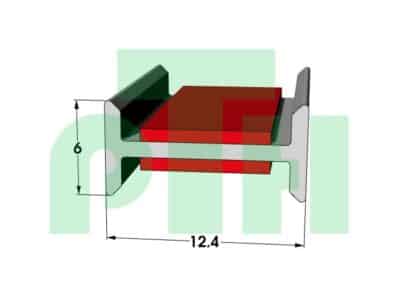

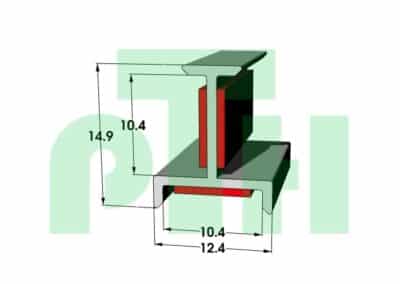

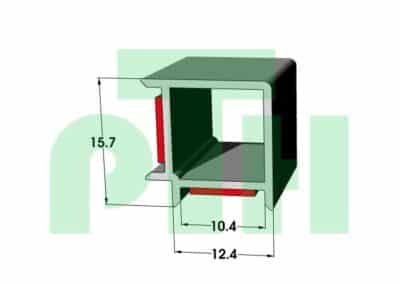

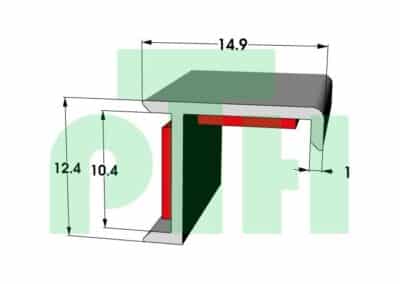

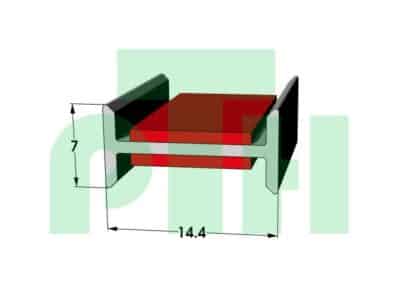

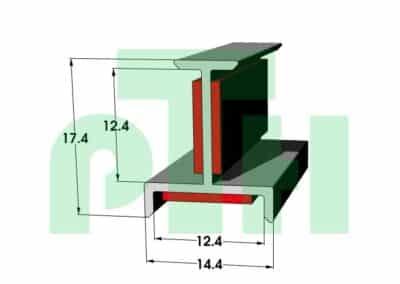

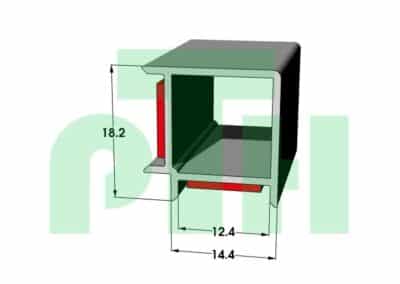

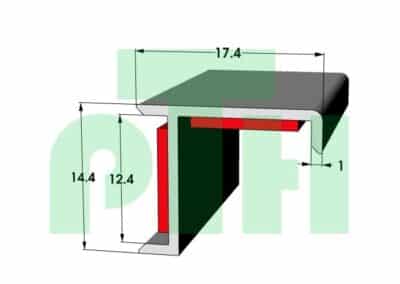

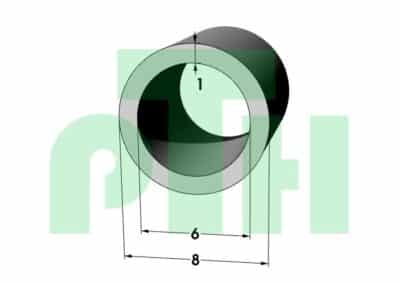

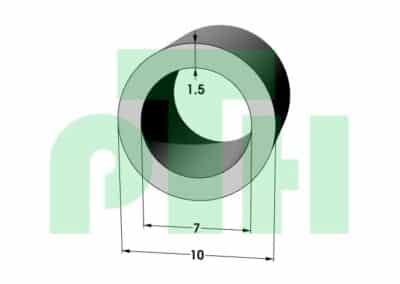

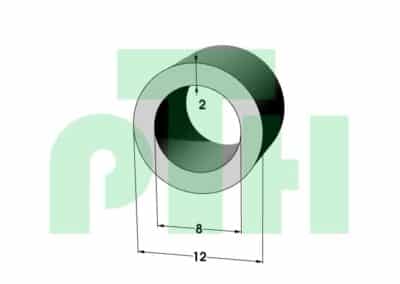

Glazing Bead and Partition Wall Profiles in Transparent Polycarbonate (PC) are extruded elements designed to secure and support glass panels or other partition surfaces. Polycarbonate is a thermoplastic material known for its transparency, impact resistance, and durability. These profiles are extruded to ensure a precise and uniform shape and are equipped with double-sided adhesive applied during extrusion, making installation easier.

Available Samples

To help you choose the solution that best suits your needs, we offer samples of our profiles upon request. This will allow you to directly evaluate the available characteristics and finishes, ensuring you select the perfect profile for your project.

Typical Applications

PTH Group’s glazing bead and partition wall profiles are used in a wide range of sectors, including:

Residential Sector

- Windows and interior doors: Polycarbonate glazing bead profiles help to keep glass panels securely in place, ensuring safety and stability.

- Interior partition walls: Used to create transparent or semi-transparent divisions within homes, maintaining the brightness of the spaces.

Commercial Sector

- Offices: Creation of separate spaces within open-plan offices without compromising natural light.

- Showcases and displays: Used in stores and showrooms to secure glass in displays or create transparent exhibition structures.

Industrial Sector

- Safety screens: Protection in industrial environments where separation between different operational areas is required.

- Acoustic barriers: Used in noisy environments to create barriers that reduce noise levels without blocking visibility.

Additional Features

- Impact Resistance Polycarbonate is known for its high impact resistance, making these profiles ideal for applications where safety is a priority.

- Ease of Installation Thanks to the double-sided adhesive applied during extrusion, installation is quick and easy, with no need for additional adhesives or mechanical fasteners.

- Versatility Suitable for a wide range of applications in both indoor and outdoor environments, thanks to weather resistance and tolerance to temperature variations.