Thermoplastic profiles and tubes, for over 30 years.

Technical Consulting

Advanced Technical Support for Customized Solutions

PTH GROUP boasts a cutting-edge technical department, equipped with advanced technical tools, capable of meeting customer requests in a short time. For the creation of a new profile product requested by the customer, the work follows phases of technical development, design, production, and consideration of the material specifications to be used.

Among the key technical equipment, we have:

-

ELECTRONIC MICROSCOPE

Product thickness measurement as well as layer/distribution of coextrusion

-

LUX METER

An instrument that quantifies the illuminance of a surface, measuring the luminous flux per unit of surface area.

Furthermore, the company boasts leading expertise in the field of coextrusion, allowing it to achieve multiple combinations of finishes.

Customized Processing and Tailored Packaging

-

Precise cutting

-

Drilling*

-

Prototyping

-

Protective coating application

-

Double-sided adhesive application

-

Special packaging

* Only for PC and subject to approval by the technical department

A product for every need

Plastic and Aluminum Profiles

PTH Group specializes in the extrusion of plastic profiles for lighting, using a wide range of polymers to meet even the most specific customer needs.

PMMA and Polycarbonate Tubes

Why Choose Us?

Discover our strengths

Quality and Control during Extrusion

-

Cutting-edge Equipment

We have specific, state-of-the-art equipment (such as magnifiers) to monitor the profile geometry during extrusion, ensuring consistent dimensions.

-

Thorough Quality Controls

We perform detailed quality checks throughout the entire extrusion production process, ensuring that every product meets our high-quality standards.

Fast Deliveries and Customized Solutions

-

In-house Technical Department

With over 30 years of experience, our technical department quickly produces custom dies on request (25/30 working days) based on drawings, also offering specialist advice. This allows us to respond quickly and accurately to our customers' specific needs.

-

Fast Deliveries for Catalog Profiles

For standard catalog profiles, we guarantee deliveries within 10/15 working days from the order. We offer customer-specific lengths for extrusions and tubes, with standard or precise cuts (available at an additional cost).

-

Customization of Optical Features

Customers can request specific light transmission percentages. We offer a detailed study of light distribution and consulting to find the optimal solution based on the use of extrusions, with the option to choose the most suitable materials for the requirements.

-

Tailored Packaging

Packaging is customized based on the length of the ordered extrusions, with options for fumigated packaging to ensure maximum protection.

High-Performance Materials and Advanced Solutions

-

Innovative Material Research

We are constantly engaged in the research and development of increasingly high-performance materials, ensuring cutting-edge performance for both profiles and tubes. We use special surface coextrusions that enhance the durability and aesthetic properties of our products, adapting them to a wide range of applications.

-

Sealing Coextrusions with Flexible Materials

We offer sealing coextrusions using flexible materials that provide customized solutions for specific needs, such as weather resistance and adaptability to different operating conditions. This allows us to meet the most complex requests from our customers while maintaining a high level of quality and innovation.

The latest news

In the LED lighting sector, especially for outdoor applications, resistance to ultraviolet (UV) rays is crucial to ensure the long-term durability and performance of components. UV-resistant coextrusion is an advanced technology that allows the creation of LED...

In the LED lighting sector, technological innovation plays a crucial role in improving performance, reliability, and design. Coextrusion with soft materials represents one of the most advanced techniques, allowing the combination of structural rigidity with the...

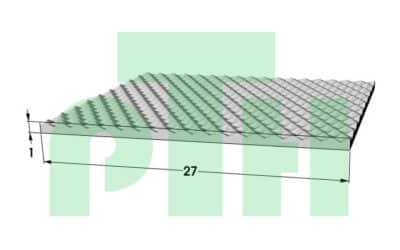

In modern lighting design, the main challenge is to combine energy efficiency with visual comfort. Microprismatic polycarbonate profiles represent a cutting-edge solution, designed to optimize light distribution, reduce glare, and enhance the visual experience in...