In the LED lighting sector, technological innovation plays a crucial role in improving performance, reliability, and design. Coextrusion with soft materials represents one of the most advanced techniques, allowing the combination of structural rigidity with the flexibility and sealing properties of elastomeric materials.

This methodology opens up new possibilities in the design and functionality of LED lighting profiles.

What is Coextrusion with Soft Materials?

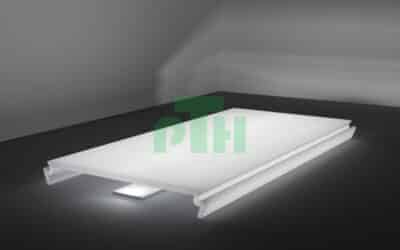

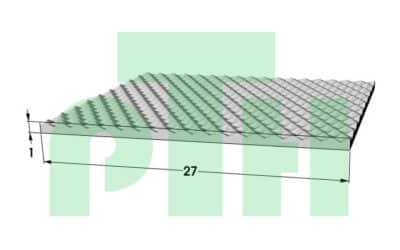

Coextrusion is a manufacturing process that integrates two or more different materials into a single continuous profile.

In LED profiles, this technique combines rigid materials like polycarbonate (PC) or PMMA with soft materials such as TPE.

The result is a profile that merges the strength and stability of rigid components with the flexibility and sealing capability of soft materials, significantly enhancing functionality and performance.

Advantages of Coextrusion with Soft Materials in LED Profiles

Coextrusion with soft materials offers numerous technical and design benefits:

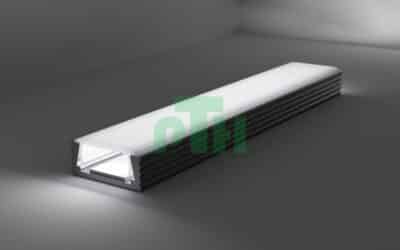

- Enhanced sealing and protection: Integrating soft materials allows the creation of built-in gaskets within the profiles, improving protection against dust and moisture and enhancing the lighting system’s IP rating.

- Ease of installation: Flexible components make it easier to assemble and adapt LED profiles to irregular or complex surfaces, reducing installation time and costs.

- Reduction of additional components: Coextrusion eliminates the need for separate gaskets, streamlining production and simplifying design.

- Aesthetic enhancement: The combination of different finishes and colors results in harmonious, integrated LED profiles that meet specific aesthetic requirements.

Applications of Coextruded LED Profiles with Soft Materials

Coextruded LED profiles with soft materials are widely used in various sectors:

- Architectural lighting: Ideal for creating continuous lighting effects on façades and interiors, ensuring perfect adherence to surfaces and uniform light distribution.

- Industrial lighting: Perfect for environments that require high protection against external agents such as dust and moisture.

- Residential and commercial lighting: Suitable for custom design projects where aesthetics and functionality must coexist seamlessly.

Common Materials Used in Coextrusion for LED Profiles

The most common materials used in coextrusion for LED profiles include:

Rigid materials:

- Polycarbonate (PC): Known for high impact resistance and excellent optical transparency.

- PMMA (Polymethylmethacrylate): Appreciated for outstanding optical clarity and UV resistance.

Soft materials:

- TPE (Thermoplastic Elastomer): Combines the elasticity of rubber with the processability of thermoplastics, ideal for gaskets and flexible sections.

Innovations and Future Trends in Coextrusion

The coextrusion with soft materials sector is constantly evolving, with research focused on:

- New materials: Development of polymers with advanced properties, such as greater thermal resistance and improved optical characteristics.

- Intelligent multilayer coextrusion: Integration of additional functionalities into a single profile, such as antibacterial surfaces, opaque shielding, or UV protection, opening new frontiers for customization and performance in LED profiles.

Why Choose Coextrusion with Soft Materials for Your LED Profiles

Choosing coextrusion with soft materials for manufacturing LED profiles means achieving lighting systems that are more efficient, aesthetically superior, and easier to install.

The integration of rigid and flexible materials allows the incorporation of gaskets directly into the profiles, improving adaptability, durability, and system protection while reducing operational time and costs.

This technology is ideal for architectural, industrial, commercial, and decorative lighting projects where aesthetics, functionality, and resilience are essential.

Contact Us for LED Profiles in Coextrusion with Soft Materials

Are you developing a project that requires LED profiles that are resistant, flexible, and high-performing?

Coextrusion with soft materials is the ideal solution.

Our team is ready to provide you with technical support, personalized consulting, and custom-made profiles designed to optimize the design, functionality, and durability of your lighting solutions.

Contact us today to discover how our coextruded LED profiles can enhance your projects.