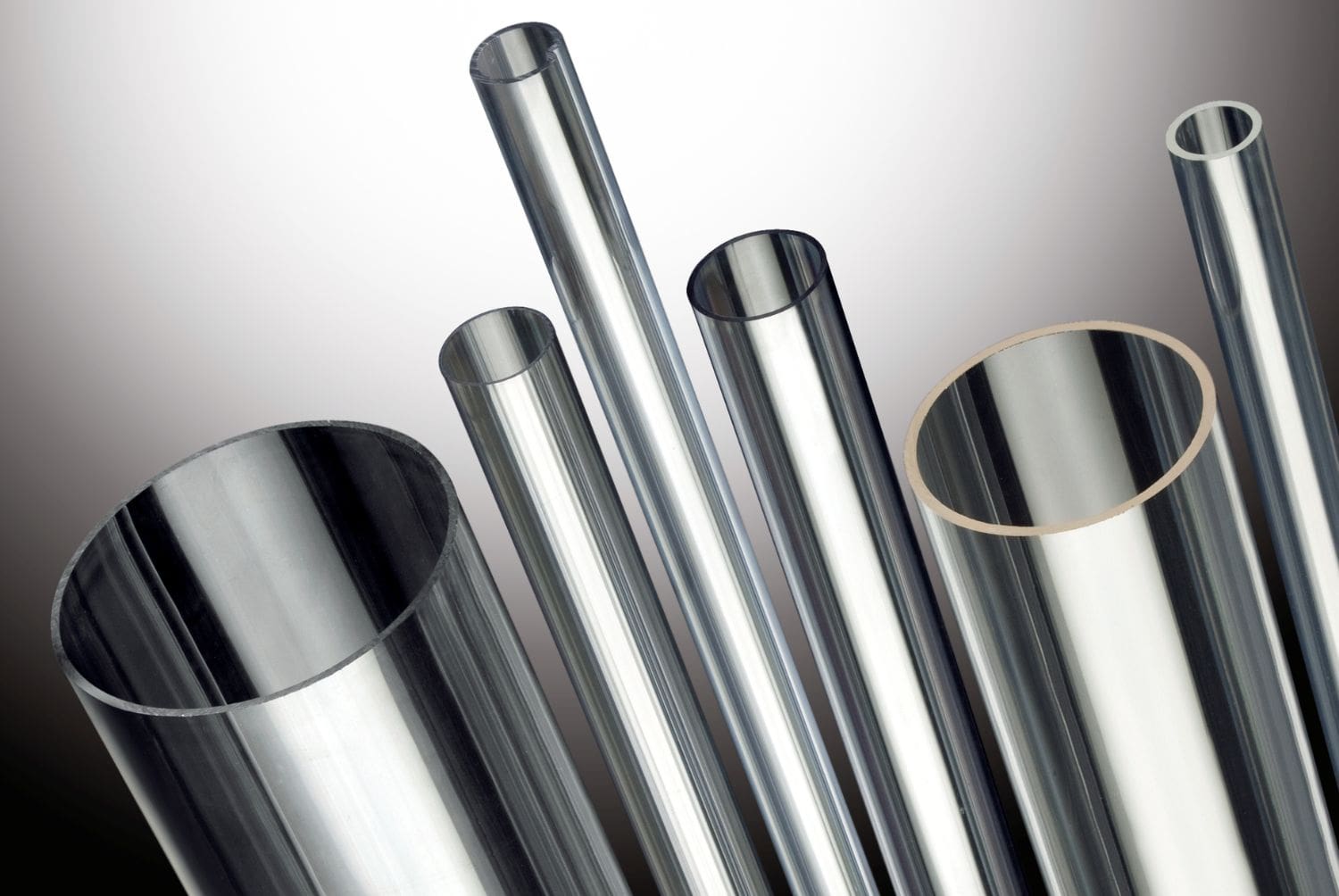

Polycarbonate and methacrylate tubes are useful for the production of numerous functional and design objects. Polycarbonate and PMMA are thermoplastic materials with specific technical and aesthetic properties- features that make polycarbonate tubes and methacrylate tubes excellent substitutes for glass tubes.

Products made from thermoplastic materials have applications in multiple sectors, in particular in the industrial sector for the production of design objects, lighting objects, and electronic objects, but also in the automotive sector. We will look at all the details together.

What are polycarbonate and methacrylate tubes?

Polycarbonate and methacrylate are products created through the extrusion of polymers in a granular form and in powder, that can be used as a finished product or as components for other projects. They are tubes made from transparent plastic, that are equipped with strong mechanical resistance and are perfect substitutes for glass tubes.

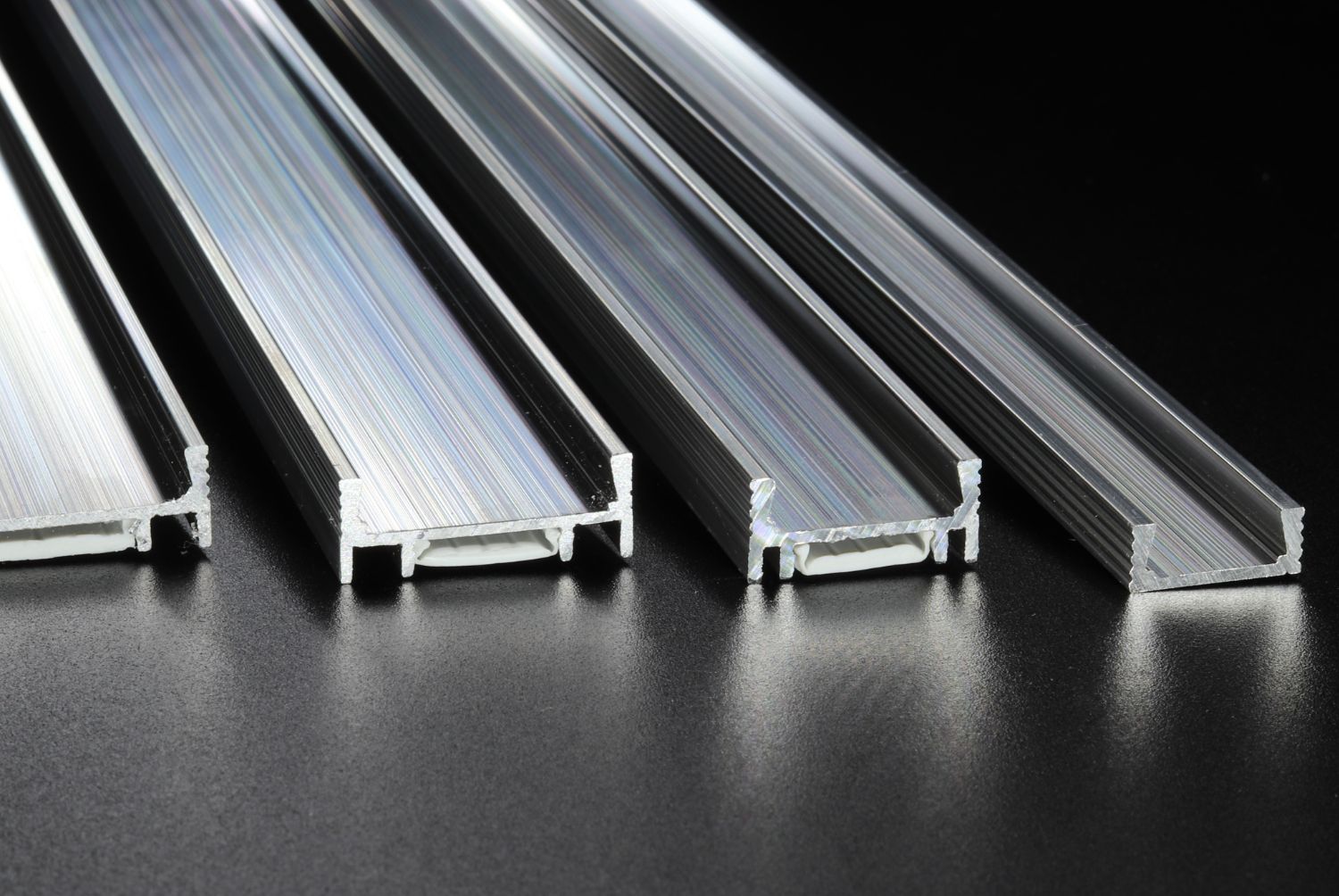

Being easy to process through the technique of extrusion, thermoplastic materials can be transformed into polycarbonate tubes and methacrylate tubes through the construction of ad hoc stamps, designed according to the needs of specific projects.

The benefits of using polycarbonate and methacrylate

Polycarbonate (PC) and methacrylate (PMMA or Plexiglass) are materials that can efficiently susbtitute glass. While similar in appearance, their features are significantly different, as are their practical applications.

Transforming the coarse material of polycarbonate is relatively easy, and once the tubular porduct is created through extrusion, the manufacturing guarantees a decade-long duration and good resistance to acids.

Therefore, one can say that polycarbonate is a thermoplastic material that is extremely malleable with heat, light, and resistance once solidified. The greatest benefits of polycarbonate are its extroardinary robustness, infrangibility, and resistance to atmospheric agents.

Methacrylate or Plexiglass, on the other hand, is a polymer that is more transparent than glass and extremely light. The benefits of methacrylate tubes relate to its impact resistance (even if it is inferior to that of polycarbonate), and, above all, its significant transparency.

PMMA yellows much less than PC, but it is not very resistant to rain, snow, and hail, and thus overwhelmingly used in the creation of objects for the interiors of buildings.

The sectors of application of polycarbonate and methacrylate tubes

There are a large number of sectors of application of tubes made from thermoplastic materials. We can mention the following:

- the automotive sector, in which the tubes can be used as spare parts for vehicles;

- the electricity sector, in which the tubes can be used as coating;

- the packaging sector;

- lighting engineering;

- the sector of production of objects for medical use.

The fields in which polycarbonate and methacrylate can be used do not end in this list, but include further sectors.

By bearing in mind the various features of polycarbonate tubes and methacrylate tubes, it is possible to choose in every case the material that best fits the productive sector in question.

Are you looking for a company that produces polycarbonate and methacrylate tubes? Get in touch

Do you need polycarbonate or methacrylate tubes?

You can count on us at PTH Group, a Lombardian company that specialises in the production of stamps for the extrusion of plastic materials.

For more than thirty years, we have offered services in the field of the processing of polycarbonate and methacrylate on the basis of latest generation software.

We at PTH Group occupy ourselves with satisfying your every need, collaborating for the creation of your personalised project for polycarbonate and methacrylate tubes.

Contact us via telephone to receive further information, or browse the range of our services on our website. You will not regret it.