In the LED lighting sector, especially for outdoor applications, resistance to ultraviolet (UV) rays is crucial to ensure the long-term durability and performance of components.

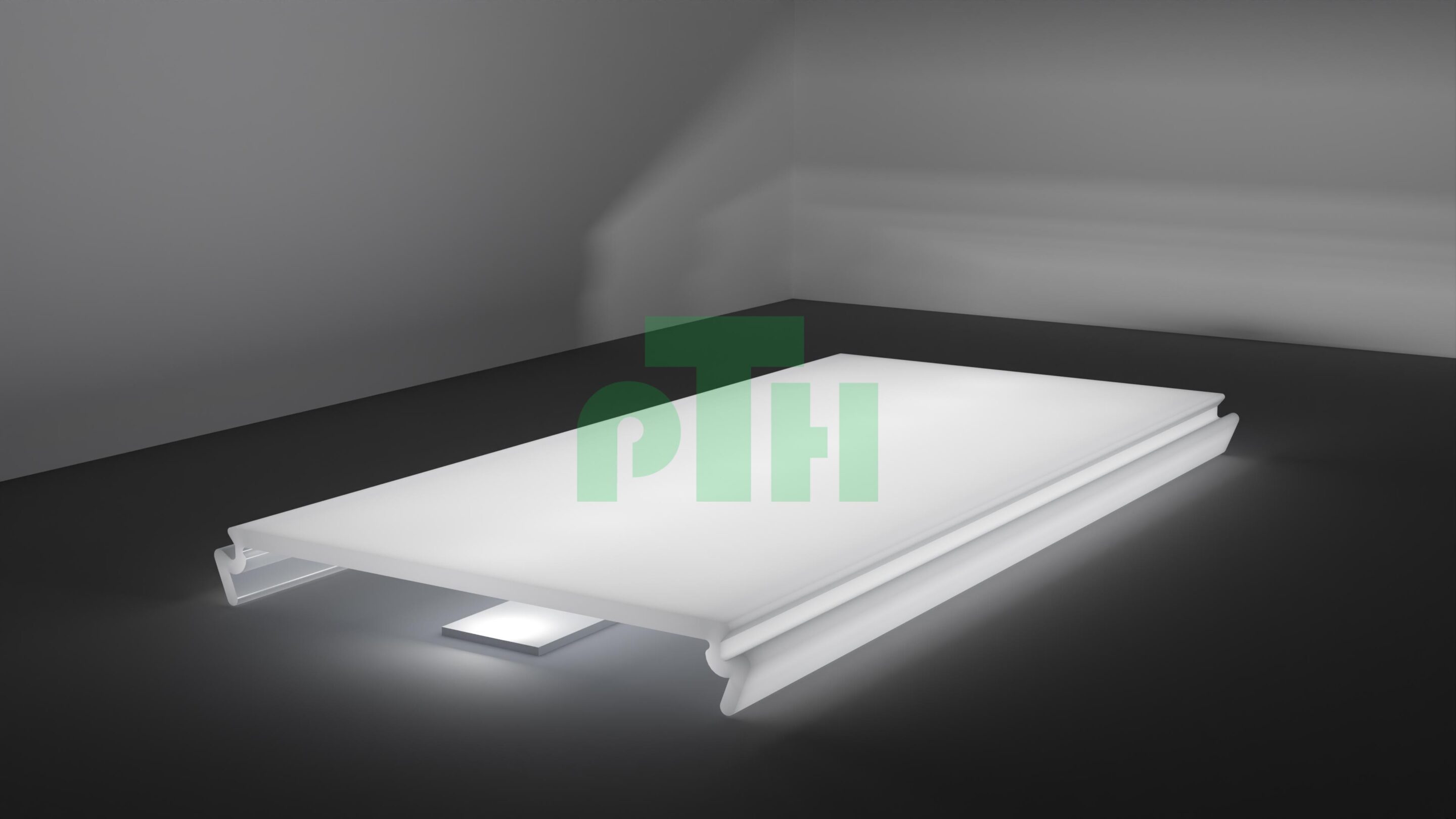

UV-resistant coextrusion is an advanced technology that allows the creation of LED profiles that are resilient, efficient, and visually stable over time, by integrating materials with different properties into a single profile to provide superior protection against the harmful effects of sunlight exposure.

What is UV-Resistant Coextrusion?

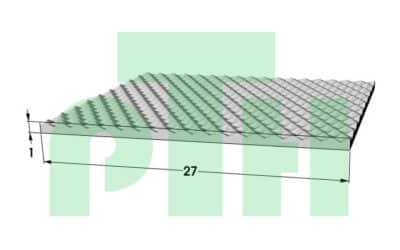

UV-resistant coextrusion is a production process that integrates an external layer with specific UV resistance properties over a base material, typically polycarbonate.

This protective outer layer acts as an effective barrier against ultraviolet rays, preventing chemical, physical, and aesthetic degradation of the underlying material.

Thanks to coextrusion, it is possible to manufacture LED lighting profiles that maintain their structural integrity, optical transparency, and aesthetic appearance over time, even under continuous exposure to sunlight.

Advantages of UV-Resistant Coextrusion in LED Lighting Profiles

Applying UV-resistant coextrusion to LED profiles offers several strategic advantages:

- Effective UV protection: The external layer shields the base material from yellowing, mechanical strength loss, opacification, and microcracks caused by prolonged sun exposure.

- Extended durability over time: UV-resistant coextruded LED profiles retain their mechanical and aesthetic properties for much longer, minimizing the risk of premature deterioration.

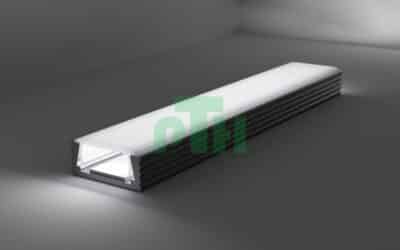

- Constant lighting efficiency: By preserving the optical material, a uniform and stable light diffusion is maintained without color alterations or loss of transparency.

- Lower maintenance costs: Greater product longevity results in fewer replacement and maintenance interventions, leading to significant cost savings.

- High performance in demanding environments: UV-resistant LED profiles are engineered to withstand not only UV rays but also temperature fluctuations, weathering, and harsh environmental conditions.

Applications of UV-Resistant Coextruded LED Profiles

Thanks to their strength and reliability, LED profiles manufactured with UV-resistant coextrusion are particularly suitable for outdoor and exposed environments:

- Outdoor lighting: Perfect for installations in gardens, terraces, architectural facades, parking lots, courtyards, and other areas subject to strong sun exposure.

- Street and urban lighting: Used in public lighting systems that must endure years of exposure to UV rays, rain, wind, and air pollution without losing performance or appearance.

- Outdoor illuminated signage: Ideal for signs, advertising totems, and information panels placed outdoors, where UV protection is crucial to maintain visibility and aesthetics over time.

Materials Used in UV-Resistant Coextrusion

The production of LED profiles with UV-resistant coextrusion relies on high-performance materials:

- Polycarbonate (PC): A base material known for its excellent impact resistance, optical transparency, and dimensional stability under environmental stress. It can be used both as the main structure and as support for the protective layer.

- UV additives: Chemical substances incorporated into the outer layer during the coextrusion process, designed to block or absorb UV rays, preventing photochemical degradation and significantly extending the service life of the profile.

Why Choose UV-Resistant Coextrusion for Your LED Profiles

Choosing UV-resistant coextrusion for the manufacturing of LED profiles means achieving lighting systems that are more reliable, durable, and high-performing, capable of maintaining their aesthetic and functional quality over time.

This technology:

- Prevents yellowing, transparency loss, and environmental stress cracking;

- Preserves optical performance even after years of sun exposure;

- Enhances the safety and efficiency of outdoor lighting installations;

- Reduces maintenance and replacement costs, optimizing system management.

If you are involved in architectural lighting, urban lighting, or the design of outdoor lighting installations, relying on UV-resistant coextrusion means choosing quality, innovation, and long-lasting performance.

Contact Us for Custom UV-Resistant LED Profiles

Do you need a highly weather-resistant and long-lasting solution for your LED lighting systems?

Contact us today and discover how our UV-resistant coextruded LED profiles can significantly enhance the performance, efficiency, and durability of your lighting installations.

Our technical team is ready to provide personalized consulting, technical support, and the design of custom-made profiles, combining UV protection, refined aesthetics, and advanced technology to fully meet your project needs.